Clatter

True Classic

Got a slacker Sunday in.

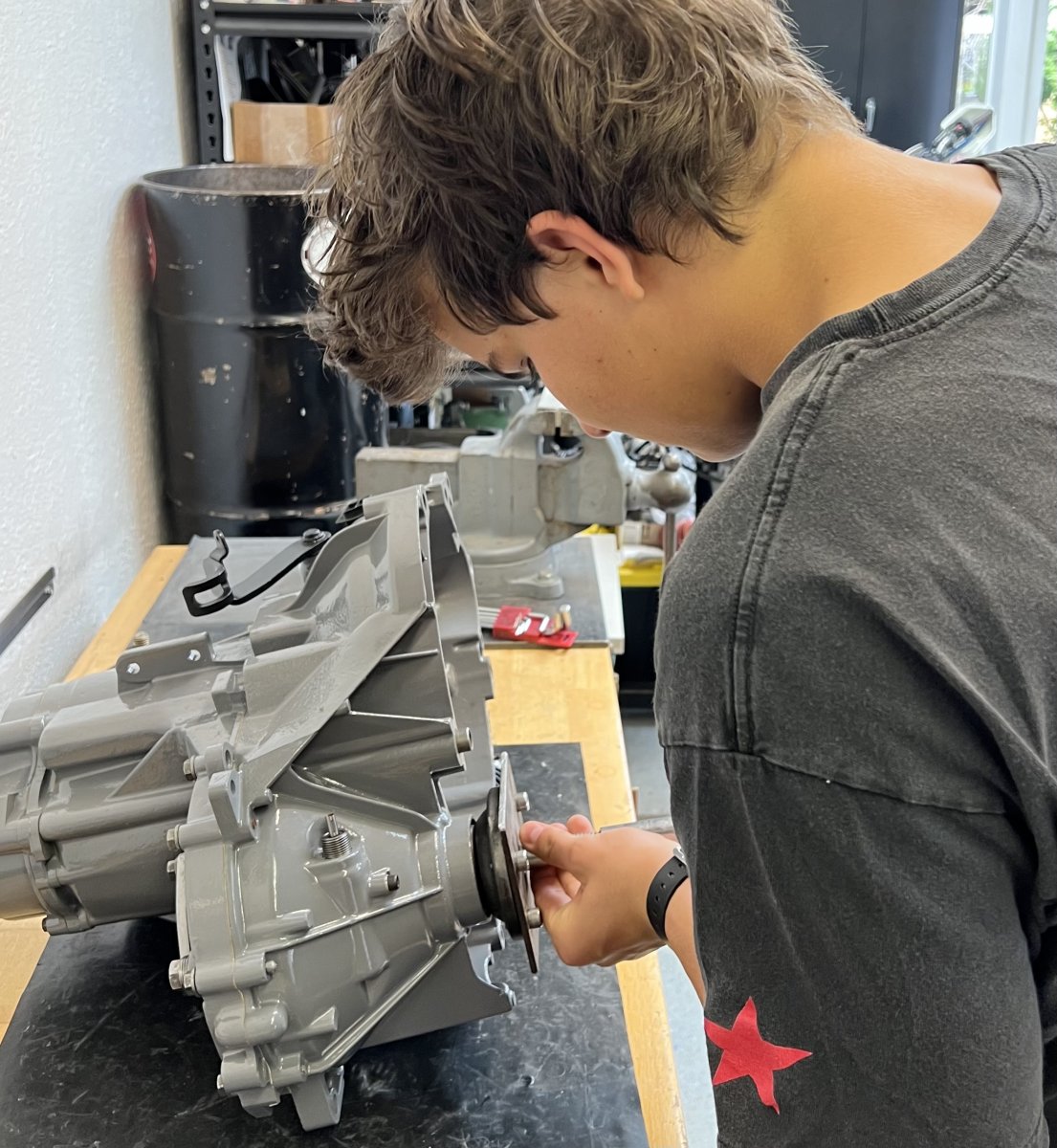

Started kinda late, then Theo had to work.

Since it was raining we dug into switching out bearings.

Started with popping CV flanges.

Much quicker when you have already made the tool.

Inner races wanted very badly to remain in place.

Ended up grinding them down thin before they relinquished hold.

LOTS of gasket scraping.

This is why you put these gaskets in dry, right?

Input shaft got nicked in the seal area.

“You didn’t tell me to watch out for that Dad”

Price of involving them i guess…

FWIW, maybe it missed the spot under the spring where the seal actually rides/seals?

Either way,

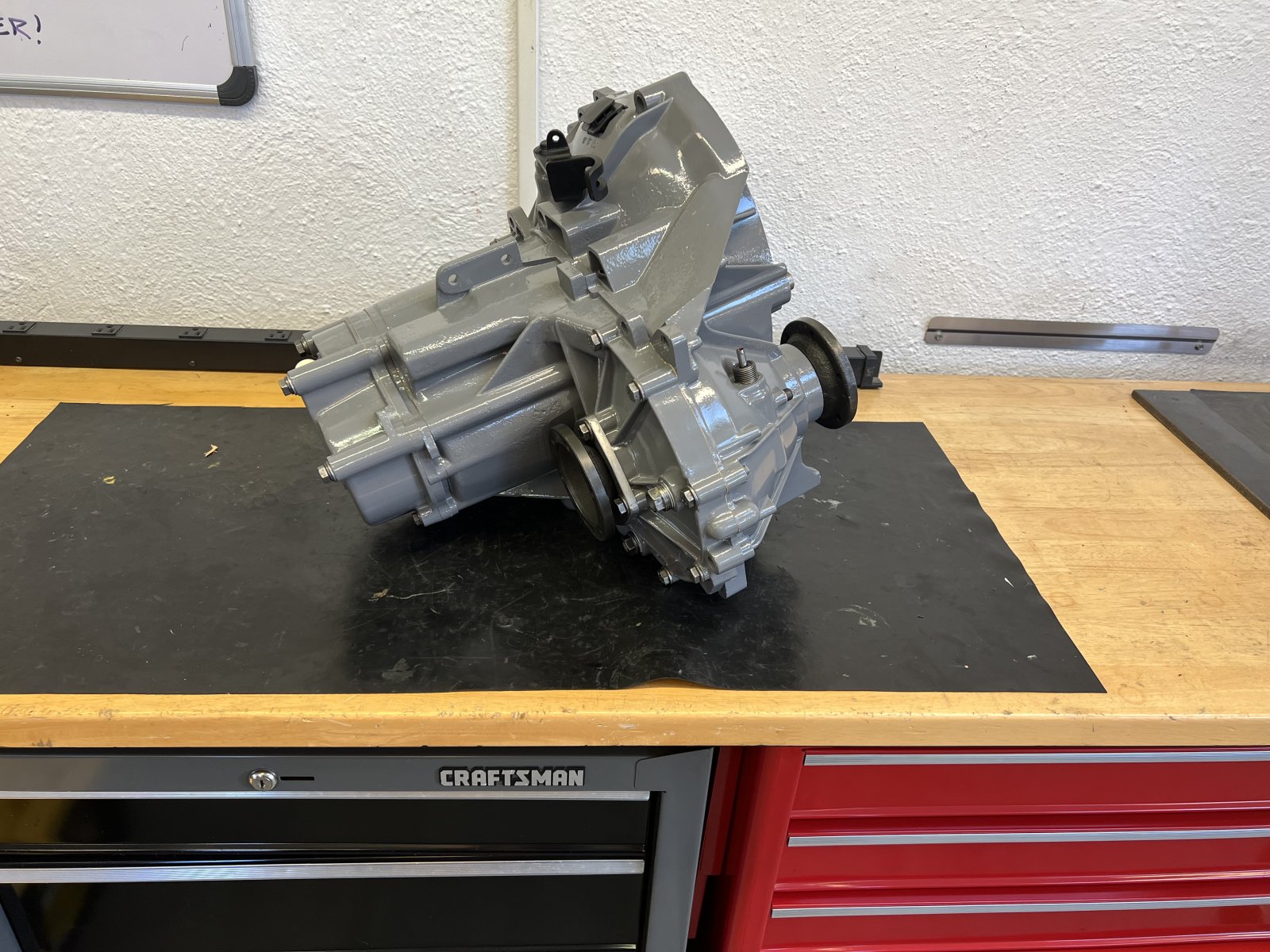

Weighing the consequences of a setback…

Wrong bearings eating a thousand bucks worth of gears, forks and sliders,

Versus a nicked shaft leaking oil and ruining a clutch disk,

We’ll call it two steps forward and one back.

I’m not paying $200 or so plus shipping for another input shaft and waiting for this thing to get out of my way.

Maybe it won’t even leak.

Went ahead and buttoned it up after he went to work.

Ever get this sense of deja vu?

Started kinda late, then Theo had to work.

Since it was raining we dug into switching out bearings.

Started with popping CV flanges.

Much quicker when you have already made the tool.

Inner races wanted very badly to remain in place.

Ended up grinding them down thin before they relinquished hold.

LOTS of gasket scraping.

This is why you put these gaskets in dry, right?

Input shaft got nicked in the seal area.

“You didn’t tell me to watch out for that Dad”

Price of involving them i guess…

FWIW, maybe it missed the spot under the spring where the seal actually rides/seals?

Either way,

Weighing the consequences of a setback…

Wrong bearings eating a thousand bucks worth of gears, forks and sliders,

Versus a nicked shaft leaking oil and ruining a clutch disk,

We’ll call it two steps forward and one back.

I’m not paying $200 or so plus shipping for another input shaft and waiting for this thing to get out of my way.

Maybe it won’t even leak.

Went ahead and buttoned it up after he went to work.

Ever get this sense of deja vu?

Last edited: